Hoffman La Roche AG completed the construction of phase one of their new vitamins and minerals premix plant at Isando, in the Republic of South Africa, in June 2002. The facility was inaugurated by Dr Marcus Altwegg, head of Hoffman La Roche Vitamins and Fine Chemicals division, on 25 June 2002.

BUSINESS SOLD TO DSM

The business was sold to the Dutch chemicals firm DSM in late 2002, in a deal worth $2.24bn. Early in July 2002 Roche instigated negotiations with DSM for the sale of its entire vitamin and premix manufacturing business. Roche, along with other European companies, was fined in the US and Europe after being found guilty of operating a price-fixing cartel for vitamin and nutritional products.

“Roche was fined in the US and Europe after being found guilty of operating a price-fixing cartel for vitamin and nutritional products.”

The sale went ahead with closure of the deal in October 2003. The sale price negotiated was $2.24bn (€1.750m) and 2.24 million shares in DSM to be issued to Roche. Roche had dropped the price by €200m because of the legal issues surrounding price controlling and also retained liability for court costs and compensation arising from these legal issues.

Roche holds 42% market share worldwide in this business and is the world’s leading supplier of vitamins and carotenoids. DSM had no other vitamin and premix business interest and so avoided monopoly investigations by European government bodies.

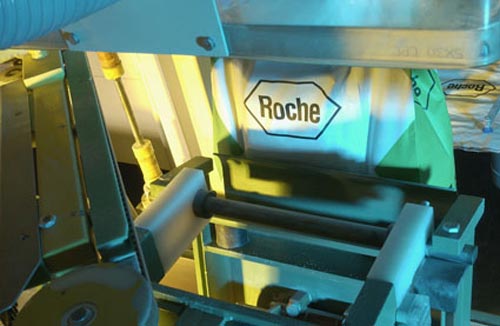

ISANDO FACILITY

The facility manufactures vitamin premixes for the food and pharmaceutical industry in South Africa and surrounding African nations, such as Nigeria, Ghana and Kenya. The facility works in cooperation with UNICEF in producing the vitamin premixes necessary to fortify basic foodstuffs in under-developed African nations.

ISANDO PREMIX PLANT PROJECT

Construction of the premix plant at Isando was started in the first half of 2000. The new facility entered full commercial scale production a little later than first planned in 2002. The plant was constructed at an estimated cost of 30m Rand ($2.7m).

This facility was the first phase of a larger project. The subsequent phase, which was completed in early 2004, manufactures vitamin premixes for animal nutrition. The total value of the entire project is estimated at $6m. The capacity of the first phase facility was 1,400t/y. The much larger second phase took production to 3,000t/y by mid-2004.

THE PREMIX MARKET BURGEONS

In the pharmaceutical industry, vitamins are used in supplement preparations such as tablets or capsules. Since companies have begun moving away from using single vitamins to fortify their products and towards multiplicity, the services of premix plants have been in great demand. This has strengthened the premix industry considerably. It is for this reason that a number of premix plant projects have been initiated by leading pharmaceuticals suppliers. These include new Roche premix plants in Poland and at El Salto, Mexico. The company has a total of 48 premix facilities around the world.

Problems have arisen in the vitamins market in recent years due to increased competition from vitamin manufacturers in China who can produce cheaper products and also by the increasing cost of raw materials. The price increases are inevitably linked to the price of crude oil.

TEAVIGO: A RECENT SUCCESS IN SOUTH AFRICA

“DSM is looking to boost revenue by producing products from plant raw materials. A recent success story is Teavigo.”

DSM is looking to boost revenue by producing products from plant raw materials. A recent success story is Teavigo, which is a purified, concentrated form of the green tea active epigallocatechin gallate (EGCG) known as a potent antioxidant. This was developed by Roche prior to the sale to DSM.

Teavigo has achieved GRAS (generally regarded as safe) status from the US FDA and is now being incorporated into a wide range of foods. Prior to this the compound was incorporated into commercial food stuffs in South Africa.

COMBATING THE HIDDEN HUNGER PHENOMENON

Vitamin and mineral deficiencies prevent some 30% of the world’s population from achieving their full mental and physical potential. This phenomenon is often referred to as ‘hidden hunger’.

Food fortification is designed to combat the ‘hidden hunger’ problem by delivering foods rich in micronutrients to large populations, especially in developing countries. The plant at Isando can now produce the necessary vitamin A, B and mineral premixes to supplement basic foodstuffs and reduce the ‘hidden hunger’ problem. The plant is responsible for the supply of vitamins and nutritional mixes to its neighbouring countries in Africa.